INNOVATION

From the ruler to the robot, we further a centuries-old science every day.

Our dedicated innovation team works to increase our calibration scope, shorten turnaround and improve the customer experience.

Projects include:

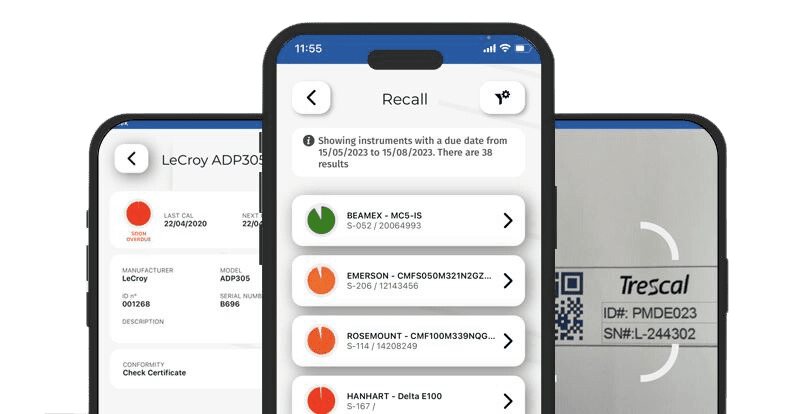

With the Trescal App, you can view your entire equipment inventory, scan instruments to view their calibration certificates and request service quotes, all from your phone. It allows you to save time and produce efficiently. Seamlessly connected to your customers portal, the app allows you to:

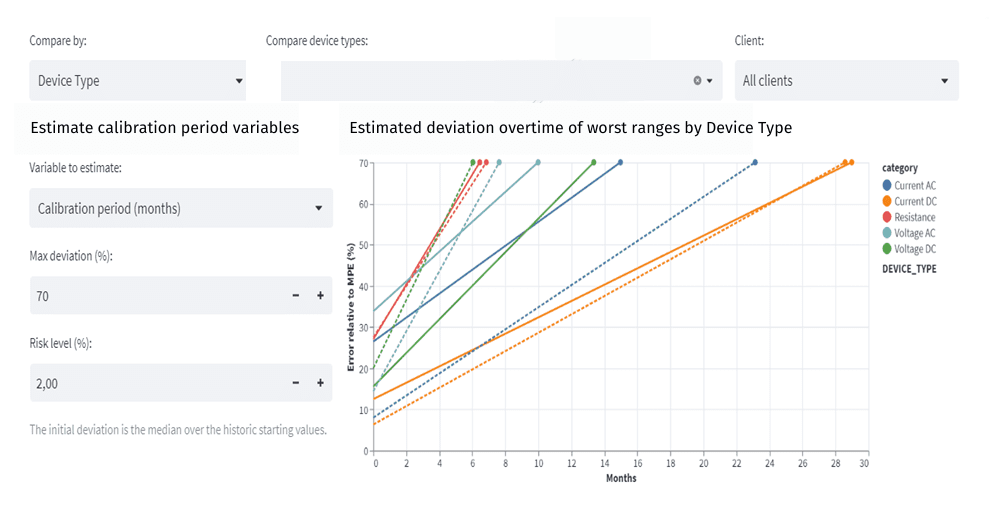

To help you plan your production around instrument downtime, our predictive model calculates the suggested time interval for your next calibration based on the last intervention and the given risk level.

Proactive calibration enables you to:

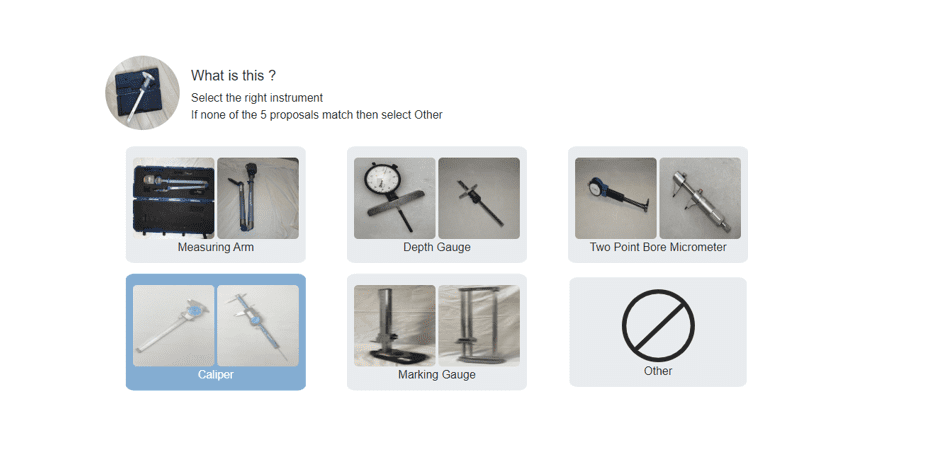

To reduce logistics turnaround time, our Optical Recognition Tool scans the instrument to identify it upon arrival at the lab. The tool is powered by artificial intelligence trained with machine learning. This allows:

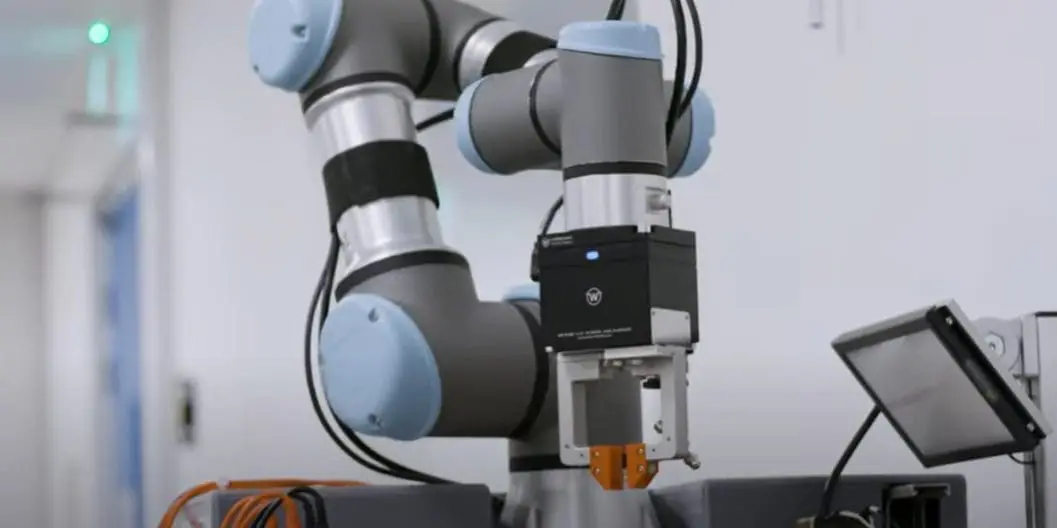

Your equipment requires fast and efficient calibration. Digital multimeter (DMM) and gage block robots can automatically calibrate dozens of tools within a few hours.

We reduce turnaround time thanks to:

Trescal’s asset management maximizes your efficiency with documentation, apps and location tracking. We are providing innovative solutions to your calibration needs.

Explore the principles of traceability and uncertainty in calibration and gain an understanding of their interdependence.

Discover the critical role of calibration in industrial manufacturing. Learn how it mitigates risks, reduces costs, and ensures compliance with regulations.