Measurement has underpinned human progress for centuries from ancient trade to modern engineering. Today digitalization accelerates this progress by transforming calibration into a smarter, connected and data-driven service. All accurate measurement relies on precise calibration, the process of ensuring an instrument provides measurement readings within specified limits. But as industries become more complex, the traditional one-size-fits all approach to calibration must advance alongside.

We collaborate with our clients to develop custom solutions that address their complexities by leveraging innovative digital tools that improve the industrial calibration experience.

Digital tools transforming our calibration approach

We commit to innovation by deploying tools that deliver insights and control over calibration processes.

Real-time instrument tracking for enhanced visibility

Know the exact location and status of your instruments at every stage of the calibration process thanks to Tag n’Track solution. It provides real-time updates on the location and status of our clients’ instruments throughout the calibration process, ensuring operational transparency.

Simplify the management of your instrument fleet

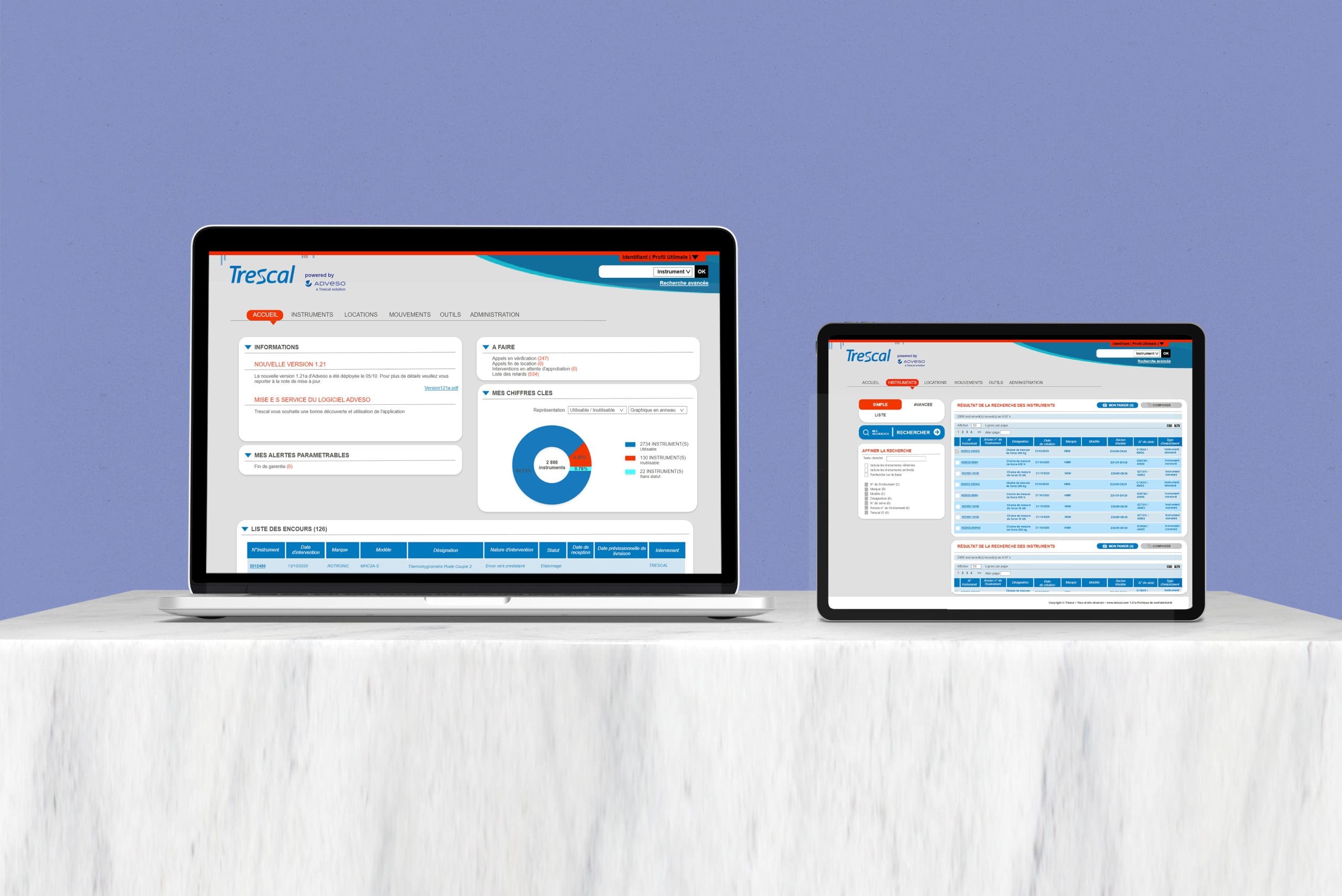

Fully online and easy to use, Adveso asset management helps companies manage and optimize metrology activities. Via the app or online platform, you can make calibration requests, track performance indicators and manage measuring instruments. You can consult instrument identity cards by the search function or scan instrument labels with your phone’s camera. Trescal can customize Adveso to interface with your information system: ERP, company directory, connected measuring instrument, etc.

Calibration certificates at your fingertips

Instantly access calibration certificates by scanning your instruments on Trescal App. You can view your entire equipment inventory and request service quotes, all from your phone. It allows you to save time and produce efficiently. In just a few taps clients can simplify communication and reduce equipment downtime.

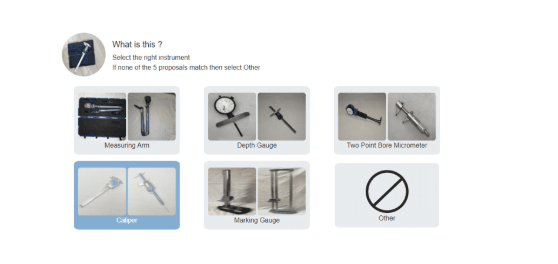

Optical recognition of instruments helps logistics reduce turnaround

Upon arrival at our laboratory, a camera scans your instrument for identification thanks to our Optical Recognition Tool. It can quickly recognize 8 domains, 128 subfamilies using an exclusive database of +3,000 images, which we continuously enrich. The tool is powered by artificial intelligence trained with machine learning. The supervisor portal allows for oversight, correction and prediction improvement. You can benefit from a quicker turnaround because new technicians can identify equipment as quickly as experienced technicians. To continuously improve in the future, we can expect a complete automation with AI-powered optical character recognition to further improve reliability.

Innovative solutions that drive precision performance

Our mission is to empower industry performance through the highest quality of precision.